In the realm of modern artistry and design, cut blue glass paired with sandblasting techniques stands prominently, offering a blend of visual allure and practicality. These methods, revered for their artistic depth and versatility, enable the creation of detailed patterns, textures, and effects that transform ordinary glass into extraordinary art pieces. Cut blue glass and Sandblast, celebrated for its deep and vibrant blue hue, and sandblasting, known for its ability to etch and frost glass surfaces, come together to form a perfect union for various artistic and functional implementations.

Introduction: Exploring the Elegance of Cut Blue Glass and Sandblast

In the world of contemporary design and craftsmanship, cut blue glass and sandblasting stand out as two techniques that marry artistic expression with functional beauty. These methods are not only captivating but also highly versatile, offering endless opportunities for creating intricate patterns, textures, and visual effects on glass surfaces. Cut blue glass, known for its rich, vibrant hue, and sandblasting, a process that etches the surface of glass to create a frosted texture, have been used in various artistic and practical applications, from high-end decor to architectural elements. Cut blue glass, as the name suggests, involves cutting the glass into desired shapes, often using a diamond wheel or water jet to achieve precise lines and angles.

Types of Blue Glass

When discussing cut blue glass, it’s essential to recognize the different types available:

- Cobalt Blue Glass: Known for its richness and intensity, cobalt blue glass is a popular choice for decorative items, lighting fixtures, and tableware.

- Turquoise Glass: This lighter shade brings a fresh and tropical vibe, often used in coastal-themed decor and jewelry.

- Sky Blue Glass: Featuring softer tones, sky blue glass is commonly utilized in projects that aim to convey tranquility and peace.

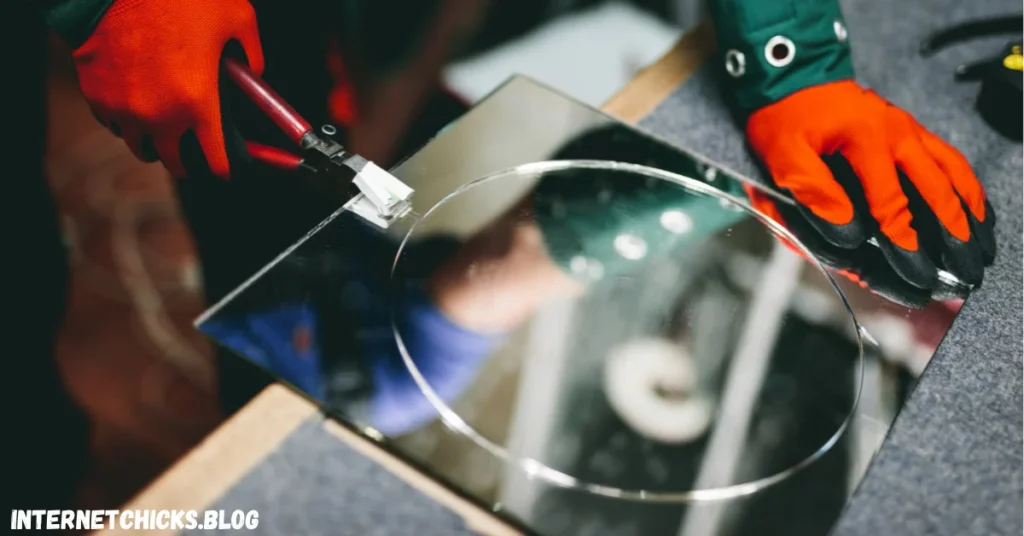

The Art of Cutting Blue Glass

Cutting blue glass is an art form in itself. Whether for crafting decorative items, window designs, or functional objects, the cutting technique can dramatically affect the final appearance of the piece.

Tools for Cutting Glass

To achieve precise and clean cuts on blue glass, artists need the right tools:

- Glass Cutter: A handheld tool with a hardened wheel that scores the glass surface.

- Running Pliers: Used to break the glass along the score line.

- CNC Machine: For more intricate, controlled cuts, a Computer Numerical Control (CNC) machine can be employed, allowing for elaborate designs and patterns.

Read More: humblewood tila stats

Techniques for Cutting Blue Glass

The cutting process involves careful planning and execution:

- Marking the Glass: Before cutting, the design should be clearly drawn or marked on the blue glass surface. Using a marker that is easy to remove later is advisable.

- Scoring the Surface: With the glass cutter, score the glass by applying even pressure while dragging the cutter across the marked line.

- Breaking the Glass: Using running pliers, align the score line with the edge of the pliers and apply even pressure to break the glass. This process requires a steady hand and practice to achieve satisfactory results.

Maintenance and Care of Cut Blue Glass

After creating beautiful cut blue glass pieces, proper care is essential to ensure longevity:

- Cleaning: Use a soft cloth and a mild detergent solution for cleaning. Avoid abrasive cleaners that could scratch the glass surface.

- Storage: Handle with care and store pieces in padded or cushioned areas to prevent chipping.

- Display: When displaying, avoid direct sunlight for extended periods, as this can affect the color and clarity over time.

The Technology Behind Cut Blue Glass and Sandblast

The techniques used to craft cut blue glass and sandblast it are deeply rooted in both traditional craftsmanship and modern technology. The cutting process, whether done manually or with water jets, involves highly specialized tools and expertise. Water jets, for example, are capable of making extremely precise cuts, which are crucial for creating the sharp lines and intricate designs typically seen in cut blue glass pieces.

Sandblasting, on the other hand, relies on the application of compressed air to direct abrasive materials, such as sand, at the glass. The process is controlled to achieve specific textures, from a light frosted effect to deeper, more intricate designs. Modern sandblasting machines can offer an incredible degree of precision, allowing artists to create highly detailed patterns that would be difficult to achieve by hand.

The Technique of Sandblasting

Sandblasting works in tandem with cut glass to add texture and design. This technique involves propelling abrasive materials, such as fine sands, against the glass surface under high pressure to etch or frost it. You can meticulously control this process to yield a variety of finishes, from a subtle matte to complex, multi-layered patterns. Artists might utilize stencils or choose freehand techniques to impart unique designs, thus transforming each piece into a distinctive work of art.

Overcoming Challenges in Creating Cut Blue Glass and Sandblast

While the process of creating cut blue glass and sandblasting it is highly rewarding, it does come with its challenges. The hardness and brittleness of glass make it difficult to cut, and improper handling can lead to cracking or breaking. Additionally, achieving precise designs with sandblasting requires a delicate balance of air pressure, abrasive material, and time.

Another challenge is the complexity of working with blue glass, as the color must be evenly distributed throughout the material. Variations in color or transparency can affect the final result, requiring careful quality control during the production process.

Cut Blue Glass and Sandblast: Sustainability and Future Trends

As sustainability escalates as a pressing concern, production methods involving cut blue glass and sandblasting are adapting accordingly. Given its recyclability and durability, glass is a sustainable choice. Consequently, efforts are intensifying to render the sandblasting process more environmentally friendly, notably by employing recycled glass and less harmful abrasives.

The future appears exceptionally promising for cut blue glass and sandblast, especially as technological advancements such as 3D printing increasingly integrate with traditional glass cutting and etching methods. We expect this fusion to yield even more precise and intricate designs. Moreover, the growing demand for sustainable and eco-friendly art forms is likely to encourage innovations that minimize environmental impact while maximizing artistic expression.

FAQs

What is cut blue glass?

Cut blue glass refers to glass pieces crafted from vibrant blue-hued material, shaped and styled using techniques like diamond cutting or water jet precision to create intricate designs and functional items.

What is sandblasting, and how is it used on glass?

Sandblasting is a technique that involves propelling fine abrasive materials onto a glass surface using compressed air to etch or frost the glass. It can create unique textures and patterns, enhancing the visual appeal of the glass.

How does sandblasting differ from other glass etching methods?

Sandblasting uses abrasive materials under high pressure for a more versatile range of effects, from light frosted finishes to deep, detailed carvings. Other methods, like acid etching, use chemicals for surface modification but may lack the depth and precision of sandblasting.

Is cut blue glass durable?

Yes, but it requires proper care. Avoid using abrasive cleaners, protect it from impact, and minimize prolonged exposure to direct sunlight to preserve its color and clarity.

Conclusion

The fusion of cut blue glass and sandblasting represents a remarkable blend of artistry, craftsmanship, and technology. From the vibrant hues of blue glass to the intricate textures achieved through sandblasting, these techniques transform ordinary glass into extraordinary works of art and functional masterpieces. Whether used in decorative pieces, architectural designs, or contemporary art, their versatility and visual appeal make them a preferred choice for both traditional artisans and modern designers.

Stay Connected: Internetchicks.blog